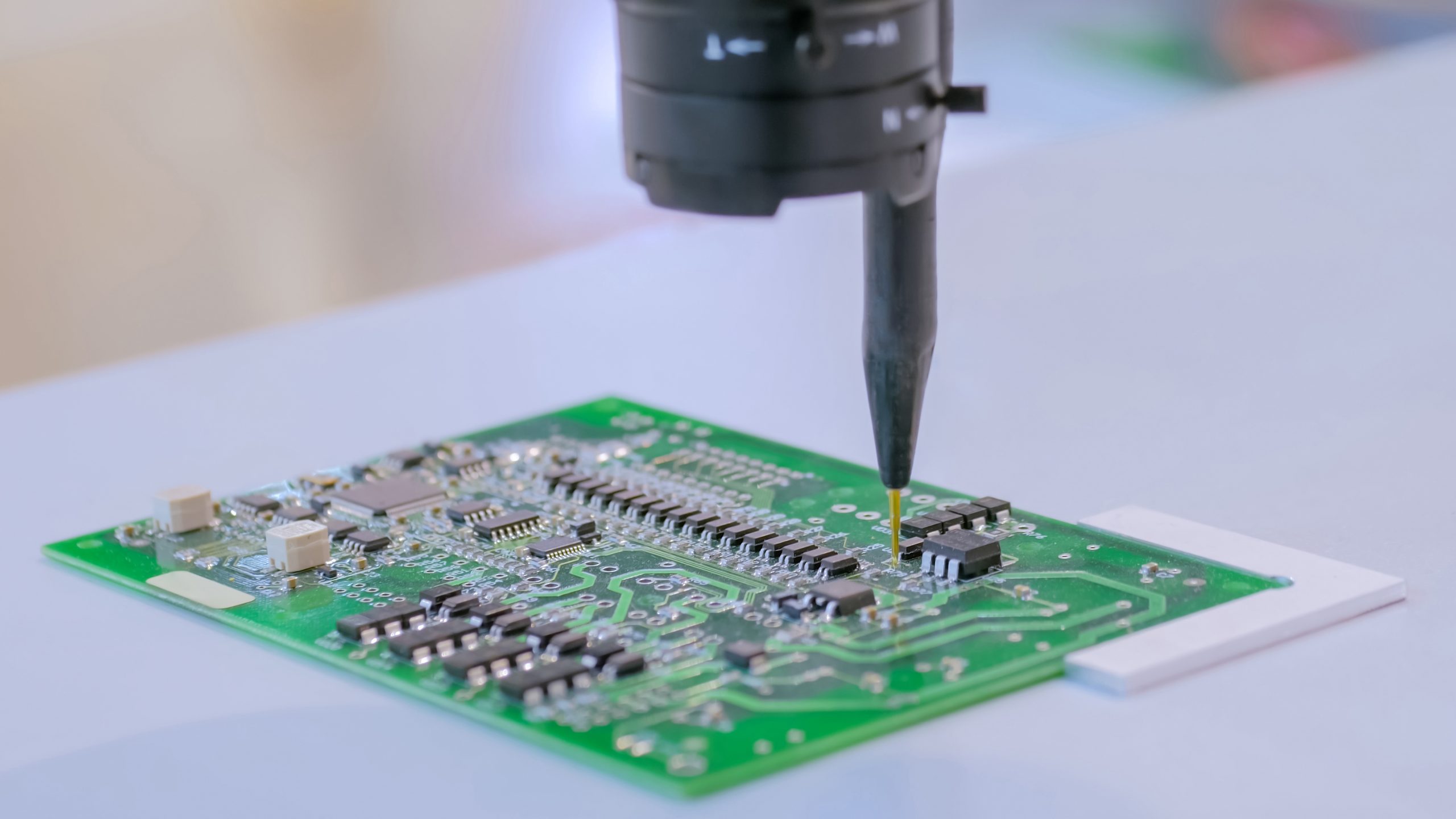

There are many qualified specialists and modern equipment, DLED will perform high-quality mounting and assembly of printed circuit boards. Assembly is the process by which components are installed on a printed circuit board. For assembly, we can use your or our boards and electronic components. Many specialists will carry out the installation of printed circuit boards both manually and automatically. A printed circuit board with electronic components located on it is called an electronic module.

The circuit board assembly consists of the following stages:

- Assembly of components on the board;

- Washing the board from the flux;

- Coating with a protective varnish.

The main method of connecting components to the board is soldering, the essence of which is to glue the parts together with solder. Soldering creates a permanent connection between board conductors and components. For the most durable connection by soldering, the parts are treated with flux – a material for chemical processing.

There are wave soldering, oven soldering, selective soldering, non-contact soldering and laser soldering.

- Wave soldering is a type of soldering for lead components in which a wave of molten solder is created by mechanical activators. The board is carried over this wave and the leads of the components are soldered to the surface of the board.

- Oven soldering is a type of soldering for planar components in which solder paste is applied to the board where the components are placed. Then the board is placed in a special oven, where the components are soldered.

- With selective soldering, selective components are installed, and the board heats up only at the place of soldering.

- Non-contact soldering reduces heating time.

- Light guides and laser diodes are used for laser soldering.